LAB NOTES & SAFETY NOTICE

For educational purposes only. Content reflects personal, non-professional formulation experiments and is not instructional.

No formula or information on this site is intended for commercial use, consumer application, or third-party use.

Accessing this content means you accept all risks and full responsibility for safety, testing, legal compliance, and outcomes.

[Full Legal Disclaimer & Safety Requirements]

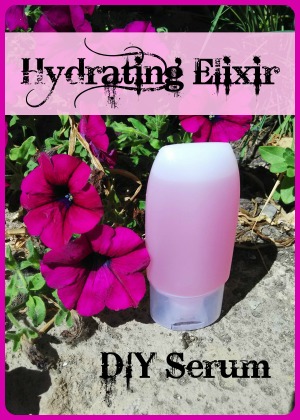

Hello Hello! 😀 Today I share one of my last experiments in the home “lsab”. Where I live, we had days over 40°C, and I just wanted something that felt icy and refreshing. I decided to formulate a serum that behaves perfectly when stored in the fridge—though I always remind myself: even if it’s cold, THERE IS NO ESCAPE FROM PRESERVATIVES! 😀

This is an “upgraded” version of my basic Hyaluronic Acid gel. I wanted to include two salts that I usually can’t put in my lotions because my favorite polymeric emulsifiers are such picky divas when it comes to salts! But in a simple water-based serum, they are absolute stars.

The Formula I Used:

-

Water: to 100%

-

Sodium Hyaluronate (high molecular weight): 1%

-

Sodium Hyaluronate (low molecular weight): 0.5%

-

Sodium Lactate: 2%

-

Sodium PCA: 1%

-

Niacinamide (Vitamin B3): 2.5%

-

D-Panthenol: 0.5%

-

Phenonip: 0.5%

-

Fragrance oil (Rock Candy): 0.2%

Notes from my Beaker:

-

The Hyaluronic “Fuss”: I measured out the water and poured the high molecular weight HA on top. Usually, I try to be patient and let it hydrate naturally, but I was in a rush! I used a stick blender which made it cloudy at first, but after a few days, it turned perfectly transparent. I did the same with the low molecular weight version right after.

-

The Humectant Boost: I added the Sodium Lactate and Sodium PCA next. Since these are naturally found in our skin (NMF), they make the serum feel so high-performing.

-

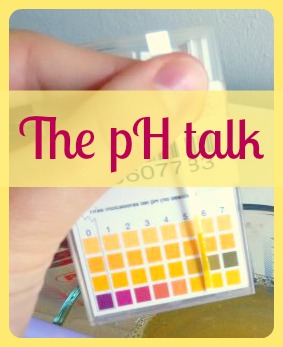

The Niacinamide Caution: I love using Vitamin B3 in the summer, but it’s so sensitive to pH. I measured mine and it was around 7.5, so I used a couple of drops of lactic acid to bring it down to pH 6.5. It’s essential to keep it in that neutral range!

-

A Touch of Pink: I added one drop of pink food colorant just to pamper myself. It wasn’t a necessity, but it looks so pretty in the bottle!

-

The Scent: I used a “Rock Candy” fragrance (the Rock Star dupe) and I absolutely LOVE it.

Final Verdict: I was a bit worried that with so many hygroscopic ingredients, it would feel sticky in the 40°C heat, but it’s not at all! I think the Niacinamide really helps with that. I only apply one drop and my skin feels unbelievably smooth. It’s the perfect “fridge treat” for the face. ENJOY! 🙂

I have added one drop of pink food colorant cause I like to pamper myself with colors. Was it a necessity? Nope.

The Fragrance Oil used in this Serum was Rock Candy from Sensory Perfection (the L**h dupe for “Rock Star”) and I LOVE IT! 🙂